OurHub

LaundRe will be based in the London area. Our site is easily accessible for all customers by train and close to city airport.

LaundRe has the capacity to finish up to 250,000 jeans p.a. and has been designed to cater for all business sizes, from major brands to bespoke and innovative, circular start ups.

We will be working closely with a pioneering textile recycler to commercialise our ReBorn R&D. With over four decades of experience and at the forefront of the fast-developing circular economy, they reuse or recycle circa 93% of the textiles received.

Our site boasts an education hub for industry and academia where we will inspire the next generation of denim scientists and build a circular, carbon positive future for UK fashion.

OurTechnology

Our innovative finishing technology and team are changing the way we produce jeans in the UK

LaserFinishing

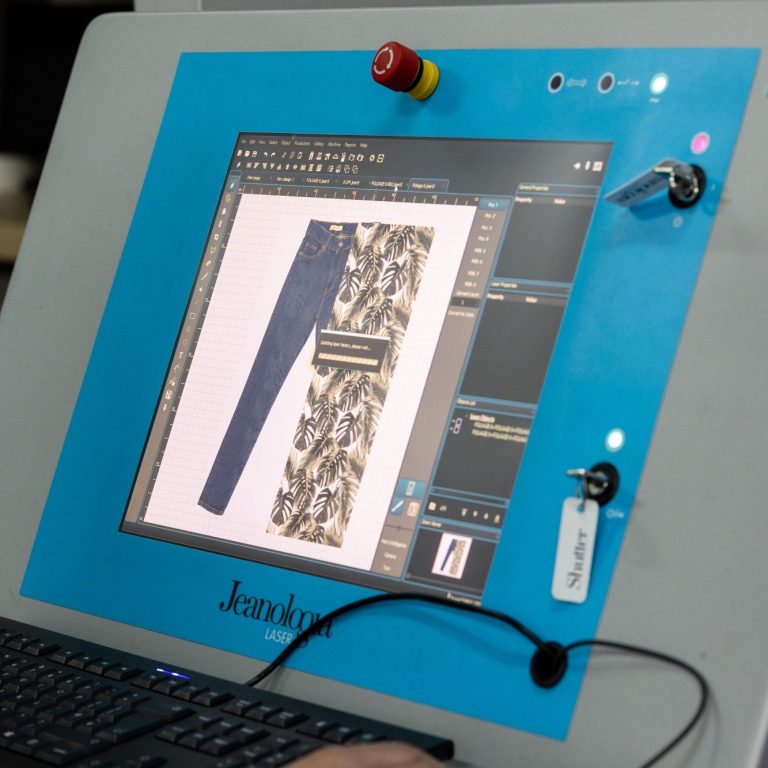

A design is visualised and approved on screen before conversion into a laser file ready for production.

We laser mark the design in seconds removing the indigo from the surface of the jean creating a worn, used look or a detailed pattern or special effect.

Digital design and laser processing replaces a labour intensive, out-dated process where workers scrape the indigo from the surface of the denim with sandpaper to create a worn look.

@jeanologia thank you for your support with our R&D trials

DigitalDesign

Using digital design systems, we create detailed patterns and fade effects, including personalisation. There are no limitations on design creativity with the photo real quality.

NebulisingTechnology

Our washing machines use nebulising systems which reduce water consumption.

Our Ozone technology changes the shade of the jean without water and safely sterilises creating 'A New', garment

Transformers Foundation salutes LaundRe as a reference in the laundry world regarding the efforts to overcome environmental and safety challenges. We consider LaundRe a state-of-the- art facility that will create innovative looks in the least impactful and safest way.

Transformers Foundation

©Copyright. All rights reserved.

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.